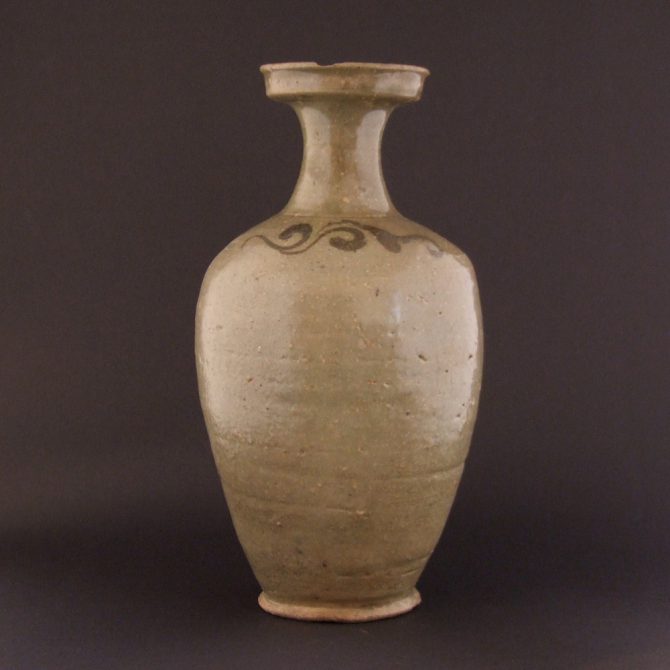

KORYO PERIOD 918 – 1392 Korean Celadon

A Korean Celadon Bottle Shaped Vase with Dish Topped Rim (Kwanggubyong) Decorated in Dark Iron Rich Slip to the Shoulder. Probably Chinsan-ri Ware, c.1050-1100.

SOLD

- Condition

- A chip to the rim 20 mm long in total, the rim partly missing due to this chip. The flared foot has large chips and smaller chips with a feint crack. The celadon glaze colour is greener than in the photographs.

- Size

- Height : 30.2 cm (12 inches)

- Provenance

- N/A

- Stock number

- 23255

- References

- For a similar Kwanggubyong form bottle decorated with a foliate design see : Korean Art From the Gompertz and Other Collection in the Fitzwilliam Museum, Cambridge, A Complete Catalogue (Yun Yong-I, Edited by Regina Krahl, Cambridge University Press 2006. ISBN 0-521-83592-5) page 158, plate 89. Yun Yong-I states that "sherds of this type have been found at kiln sites in the area of Chinsan-ri, Haenan, South Cholla province, where this bottle was probably made".

Information

Koryo Ceramics :

Korean ceramics of the Koryo Period (918 - 1392) chiefly comprise of Celadon wares, although influenced by Chinese Song Dynasty (960-1279) Yue Celadons they are distinctly Korean, although there is a geological connection between the Yue and Korean celadon kilns which might add to the similarity in appearance between the two. The distinct colours achieved by Korean potters owe much to the raw materials employed. The presence of iron and iron oxide as well as manganese oxide in the clay, and quartz particles in the glaze give these celadons their unique appearance. Firing temperatures were commonly around 1150ºC, and the level of oxygen within the kiln was dramatically reduced at some stage of the firing; this is known as a reducing, rather than an oxidizing atmosphere. Koryo celadon are often plain, but decoration included incised, carved, impressed, or inlaid designs. The inlaid designs are distinctly Korean, metallic compounds like iron oxide (black or brown), copper oxide (red), and even occasionally gold colourings were added to slip which them was rubbed into an impressed design producing the look of an inlay.